Products and services

Working with thermosetting resins requires in-depth knowledge of the material and its transformation. The products designed and manufactured by us are not only a guarantee of seriousness to our customers, but also the guarantee of total control of the services that we offer you. We are able to provide you with a wide range of high quality Glass Fiber Reinforced Polyester (GRP/SVR) products offering high performance allowing their use in a wide variety of industries.

Equipped with filament winding technology, our products resist high internal pressures. This manufacturing process consists of winding continuous glass fibers impregnated with resin around a rotating mandrel. Our fiber guiding system during the rotation of the mandrel ensures that the fibers are wound evenly, minimizing the risk of leaks.

Our revolution elbows and our reductions are also manufactured using this technology, which allows us to produce continuous radius parts benefiting from the excellent mechanical characteristics of a filament wound pipe.

All our products are manufactured to exacting specifications and meet the highest international standards.

The characteristics we give to all our products allow them to transport highly corrosive gases and fluids, including aggressive acidic agents. Very robust and flexible at the same time, they are capable of supporting extremely heavy loads thanks to rigidities greater than 5,000 N/m² as well as very aggressive environments.

Pipes

SAMTER not only offers you piping made entirely of fiberglass, but also a wide range of GRP/SVR shrink-wrapped thermoplastic piping.

Our pipes with a diameter greater than DN80 are manufactured using the filament winding process. Thanks to this process we obtain Biaxial pipes, reinforced to withstand high internal pressure as well as possible external loads exerted on them.

Diameters (DN): 15 – 3500mm

Pressure (PN): up to 32 bars

Lengths: up to 12 meters

Rigidity (SN): ≥5,000 N/m²

Accessories and fittings

Just like our piping, all our accessories with a diameter greater than DN80 made by revolution are manufactured with the filament winding process.

Our accessories are standard but can be custom made to your specifications.

Diameters (DN): 15 – 3500mm

Pressure (PN): up to 32 bars

Rigidity (SN): ≥5,000 N/m²

Drilling: DIN // ASME // EN // according to project specifications.

Equipment

We work with your engineers and technicians to provide them with experience and know-how and offer you suitable equipment in solid GRP/SVR or shrink-wrapped thermoplastic that will respond efficiently to your problem.

We carry out a compatibility study based on fluids, gases, temperatures and service conditions with the aim of offering you the materials that best suit your needs.

We manufacture a wide range of equipment such as scrubbers, quenches, washing towers, pressure tanks, absorption ducts and chimneys.

However complicated your request may be, both in terms of its geometric shape and its design, our SAMTER teams can manufacture it.

Contact us so that our teams can evaluate the manufacturing method best suited to your needs.

Storage systems

We manufacture versatile, high-quality storage solutions (fixed and/or transport) offering maximum performance. These storage solutions are designed and manufactured to allow you to store water but also a wide variety of chemicals.

Depending on your storage needs, our teams are able to offer you optimal, tailor-made solutions using specific resins that will meet your needs.

Our tanks are designed to be buried, or to be overhead (vertical or horizontal) and offer a storage capacity of up to 150,000 liters.

Security elements

SAMTER security elements are designed to be installed in industrial environments or public places, where resistance to corrosion and oxidation is essential. These elements are simple to install and can support very large loads.

Among the safety elements that we offer, we can cite gratings, profiles, stairs, secure ladders, safety doors, walkways, guardrails, manhole covers.

Coatings and waterproofing

The SAMTER coating technique is modern and effective, its aim being to prevent both leaks and bacterial disinfestations, and give durability to the covered surfaces. In order to obtain an optimal result, we apply a treatment beforehand, and in this way, our coatings can be made on almost any surface.

Among the multiple advantages of a GRP/SVR coating, we can cite durability, unalterability to temperature differences, absolute waterproofing even applied to cracked surfaces and elasticity, absorbing work movements and expansions. of the substrate.

Pre-assembly in workshop

In order to ensure a long-lasting and robust solution, SAMTER offers to facilitate and save time during final installation thanks to pre-assembly in the workshop carried out by our teams of highly qualified pipefitters.

Thanks to a detailed study of isometrics, you will be guaranteed a tailor-made solution that will integrate perfectly with existing work.

Micro Treatment Plant

SAMTER also offers you tailor-made, compact and complete wastewater treatment solutions.

These solutions ensure both their pretreatment and their treatment. In this same range of products, we also offer biological septic tanks, oil separators and grease traps.

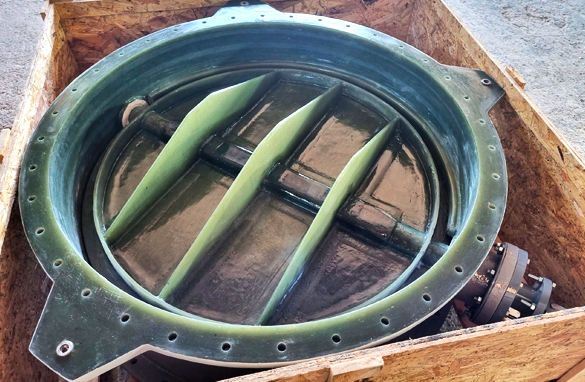

Special pieces

At SAMTER we consider ourselves artisans in the field. This is why we are able to produce parts specially designed for a specific need, such as supports, mixers or valves, among others, within specified deadlines.

We guarantee the manufacturing of molds to ensure that the parts perfectly meet your needs and meet your requirements.

Professional services

SAMTER offers you a wide range of professional on-site assistance services with the aim of guaranteeing that the installation of PRV/SVR products meets current standards. These services guarantee that your project will meet the necessary quality standards.

On-site installation

We guarantee you a full range of on-site services, from dismantling old equipment and pipes to commissioning your GRP project.

Our qualified teams therefore provide dismantling services for old piping systems or equipment, installation of new piping (buried or overhead), assembly of equipment, joints and bolts, their connection with existing installations and carrying out tests. hydraulic sealing and pressure.

Expertise

With many years of experience in the field of thermosets and thermoplastics, our best technicians travel on site to carry out a diagnosis of your pipes and equipment which have suffered damage due to poor installation, misuse or simply having undergone an premature aging.

Following our expertise, a detailed and explained report will be given to you.

Our teams are committed to advising you on the durability of the device and the continuity of its operation.

Maintenance and repair

Our maintenance service mainly intervenes for modifications of devices, for the creation of pipes but also for the repair of devices or pipes.

SAMTER undertakes, in accordance with current international standards, to carry out an in-depth study of the modifications and repairs to be carried out to ensure the sustainability of your installations. Our continuous monitoring service will guarantee the correct functioning of your installations after our intervention.

The efficiency of the SAMTER maintenance service is one of our requirements and priorities, because this service is the response to an urgent request from you.